Your Path to Accident-Free Molten Molten Metal Safety: Explosions, PPE, Forklifts, Pre-heating...

The CAST Cooperative Research Centre had three successful rounds of funding and produced many focused research outcomes, numerous post graduates and a lot of benefit to the Die Casting/ Foundry/ Cast House Industries in Australia. The educational activities included TAFE Certificate II, III and IV modules, short courses for industry, University electives and focused post graduate research programs. One of these short courses that evolved out of the TAFE and industry presentations was the molten metal safety course. The CAST CRC has allowed mjlee consult to present this material.

The course is available face to face (typically over two days including site "audit" and review of any historical site incidents) or via 4 online modules:

- Molten metal explosions

- Case study: reviewing coroner's report.

- PPE: splash testing of clothing, eyewear, shields, aprons, boots.

- Forklift shields and Work practices.

The focus is on molten aluminium in die casting shops, foundries and smelter cast houses.

For further details contact Michael LEE

Personal Protective Equipment

Molten metal explosions

The three main types of molten metal explosion are examined:

- Water/ steam (where liquid aluminium covers water; encapsulated water converts to steam; the volume expansion ejects molten metal)

- Rust/ thermit reactions (where iron oxide, and occasionally copper oxide reacts with molten aluminium with a runaway exothermic reaction)

- "Other chemical" reactions (fertilisers, powder explosions)

Coroner's report discussed

With the support of the company invovled and the Australian Industry Associations a tragic molten metal explosion in Melbourne is examined in detail. ABC news footage, extracts from the coroners report and the updated code of practice are discussed in detail and make a very powerful impact on staff attending the course

Forklift shields and Work Practices

Large furnaces require a lot of molten metal "tending" and forklifts are often used for skimming, stirring and adding metal to the furnace. Furnace windshields are an important protective barrier and are examined in the molten metal course.

Work practices, housekeeping and review of any site incidents are also discussed during the course

Reading 1: Al casthouse splash testing (2005)

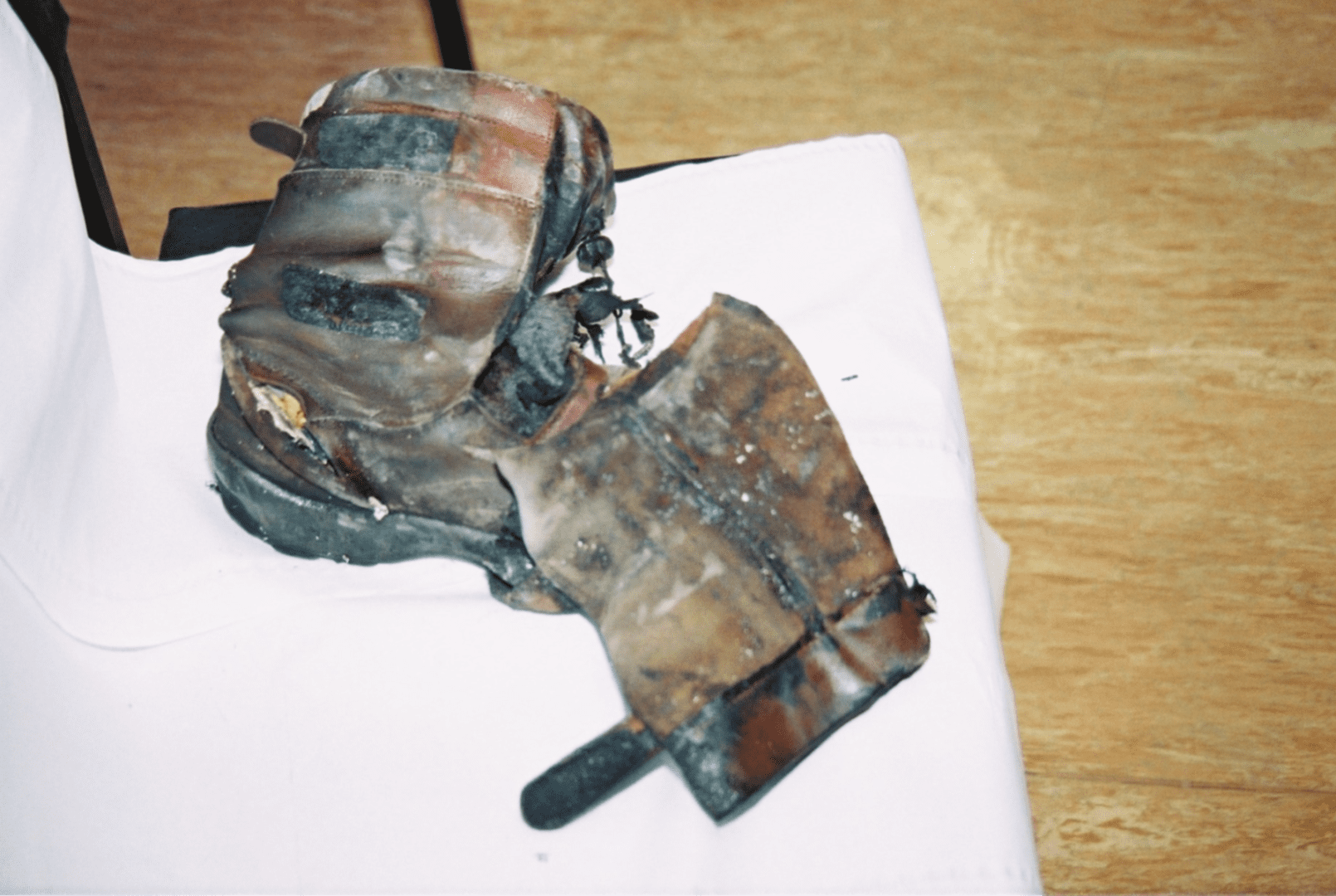

The testing carried out by CAST CRC and Comalco (Rio Tinto Alcan) focused on evaluating the effectiveness of personal protective clothing (PPE) against molten metal splash in aluminium cast houses. Testing primarily used a modified Australian/New Zealand standard (AS/NZS 4502.4) to test a variety of materials, including wool blend and cotton materials, leather aprons, socks, safety glasses, face shields, boots, and gloves.

The study reveals that wool blend materials offer greater resistance to molten metal splash compared to commonly used cotton materials. Additionally, it assesses the performance of various PPE items, including leather aprons and gloves, which tend to harden and contract upon contact with molten metal.

The study also examines the impact of molten aluminium on safety glasses and face shields, noting that while polycarbonate material melts, it does not ignite or get severely pierced by the metal.

The paper emphasizes the need for further testing to determine the most appropriate glove and boot protection in such environments.

Reading 2: Recent developments in Casthouse PPE (2009)

Key points covered in the document include:

- Injury Statistics and OH&S Issues: The paper discusses injuries in foundries, emphasizing musculoskeletal, fracture, wound, burn, and deafness-related injuries. It identifies manual handling, plant and machinery, and noise as key occupational health and safety issues.

- PPE Developments: There has been a significant shift from cotton-based PPE to wool-based clothing in the last two decades. The document also notes the trend towards high-visibility clothing to reduce forklift-related accidents.

- Specific PPE Items: The paper details various PPE items, such as foundry shirts and trousers, furnace coats, gloves, boots, socks, safety glasses, and face shields. It discusses the specific features and improvements in these items to enhance safety and functionality.

- Mobile Phone Battery Safety: A unique aspect covered is the safety concern regarding mobile phone batteries in cast house environments, highlighting the need to address new technology risks in updated safety codes.

The document concludes by underscoring the importance of the Foundry Compliance Code as a benchmark for PPE standards and the need for continuous development of PPE items.

Reading 3: Victorian Compliance Code - Foundries 2008

"Compliance Code: Foundries," created by WorkSafe Victoria, provides a comprehensive guide for ensuring occupational health and safety in foundry environments (check for updates). The Compliance Code is structured to align with the Occupational Health and Safety Act 2004 and the Occupational Health and Safety Regulations 2007. It is a detailed resource for employers, employees, and health and safety representatives in the foundry industry and is easy to read.

- Introduction and Purpose: The code aims to guide employers in foundries on fulfilling their safety obligations. It covers various aspects of foundry work, particularly focusing on the casting of molten metal, and outlines the diverse and hazardous nature of foundry environments.

- Foundry Hazards and Controls: A significant portion of the code is dedicated to identifying specific hazards in foundries, such as molten metal explosions, heat stress, burns, and exposure to hazardous substances. The code provides detailed instructions on how to manage and mitigate these risks.

- Duties of Employers and Employees: The code emphasizes the responsibilities of employers in providing a safe working environment and highlights the importance of employees taking reasonable care for their own and others' safety.

- Hierarchy of Control Measures: The document outlines a systematic approach to controlling hazards, prioritizing elimination of hazards and, if not possible, employing engineering, administrative, or PPE controls.

- Consultation Requirements: The code mandates employers to consult with health and safety representatives and employees on issues affecting their health and safety, particularly in relation to foundry-specific risks.

- Specific Operations and Safety Measures: Detailed guidelines are provided for various foundry operations such as furnace operation, material inspection, handling of molten metal, and dealing with specific risks like chemical and steam explosions.

- Personal Protective Equipment (PPE): Extensive information is provided on the selection, use, and maintenance of PPE in foundries, acknowledging its critical role in worker safety.

- Molten Metal Safety: Specific safety measures for working with molten metal, such as precautions against metal explosions, proper handling techniques, and the use of appropriate PPE, are emphasized.

- Heat Stress Management: The code discusses the risks associated with working in high-temperature environments and outlines measures to manage heat stress.

- Burns and Radiation: Safety measures to prevent burns from hot surfaces, molten metal, and radiation are detailed.

- Hazardous Substances and Dangerous Goods: The code covers the safe handling, storage, and disposal of hazardous substances and dangerous goods, highlighting the risks of chemical exposure and providing guidelines for minimizing these risks.

- Slips, Trips, and Falls: Preventative measures for common physical hazards like slips, trips, and falls in the foundry environment are outlined.

- Manual Handling: The document addresses risks associated with manual handling tasks in foundries and suggests methods to reduce these risks.

- Machinery and Equipment Safety: Safety requirements for the use of various machinery and equipment in foundries are detailed, focusing on reducing mechanical and non-mechanical hazards.

- Electrical Safety: Guidelines for managing electrical risks, including measures to prevent electric shock and fire hazards, are provided.

- Environmental and Facility Safety: The code discusses the importance of foundry layout, adequate facilities, and safe work environment design to ensure overall safety.

- Noise and Vibration Control: Measures to control noise and vibration in foundries, and the associated health risks, are discussed.

- Access Hazards: The document addresses complex access hazards, such as working at heights or in confined spaces, and provides control measures.

- Workplace Amenities and Environment: The provision of adequate workplace amenities, such as wash facilities, dining areas, and toilets, is covered.

- Foundry Buildings and Work Area Design: Specific guidelines for the design and maintenance of foundry buildings and work areas are provided to ensure safety.

- Furnaces and Furnace Tools: Safety measures specific to furnace operation and the use of furnace tools are detailed.

- Raw Material Inspection: The document emphasizes the importance of inspecting raw materials for contaminants to prevent violent reactions when introduced to molten metal.

- Implementation and Compliance: The code clarifies that while adherence is not mandatory, compliance indicates fulfillment of legal safety obligations. It also details the consequences of non-compliance.

Readings: Burns, Forklifts..

- Prevention of molten aluminum-water explosions: US Al Association

The management of forklifts around molten metal operations are very important and there are different aspects of relative importance for die casters, foundries and large scale cast houses

- A guidebook of industrial traffic management and forklift safety. Larsson etal Monash University

The three papers related to molten metal burns although relatively old are sobering reading for all first aid officers and staff working near molten metal.

- Molten metal burns: early treatment improves outcomes: Margulies etal 1998

- Molten metal burns: Kahn etal 1981

- Hot metal burns of feet in foundry workers: Pap 1966

- Self triggering reaction kinetics between nitrates and aluminium powder: Demichela 2007

Let’s Connect

Reach out to us to create a safe environment for your team where molten metal operations can thrive safely and efficiently.