Delve Into the World of Metallurgy of Overhead Lines

Metallurgy plays a crucial role in the design, construction, and maintenance of overhead lines, which are essential components of electrical power distribution systems. The metallurgical aspects of overhead lines involve the careful selection of materials and the understanding of their behaviour under various environmental conditions.

The Metallurgy of Overhead Lines course aims to provide specialist knowledge to early career engineers within the Utility networks focusing on the properties of the possible conductor fleet from concept to end of life. The course utilises the technical knowledge contained in CIGRE Technical Brochures, session papers and the broader community.

Course participants will develop their knowledge of the properties and applications of the various conductors available. Topics covered over the ten-week course (2 to 3 hours per week online Team meeting, and 1 hour per week private review/ reading/ assignment preparation)or Two to three day face to face course:

- Conductors and strength members available

- Conductor physical properties – breaking load, creep, thermal expansion, fatigue

- Line losses and Dynamic Line Rating: sun, wind and rain

- Corrosion and other degradation over time

- Asset management and design considerations; Life cycle analysis

- Vibration, ice, and bushfires: how conductors behave

The development of individual technical libraries and engineering community networking are also integral to the course.

The course participants are drawn from a range of Utilities, consultancies and suppliers.

For further details on course dates and locations/ quotes please contact Michael LEE

Course Modules

1. Introduction

Industry overview and the role of conductor selection.

History of conductor usage, development and asset management.

Discuss the relevant standards, technical papers and their access for the course

2. Metallurgy of OHL: Different materials

The range of conductors available to transmission engineers has developed with the availability of metals and materials – from copper to steel reinforced aluminium, all aluminium alloys and with composite core strength members.

The assignment this week is to review the conductor fleet currently in use and how it has developed over the years with different Utilities.

3. Metallurgy of OHL: Properties

Balancing safety, reliability, environmental footprint, and affordability. Looking at minimum specifications and actual production numbers: in built safety factor or variations?

The balancing of properties is highlighted with the assignment to compare an ACSR and AAAC and considering the quantity of steel and foundations required.

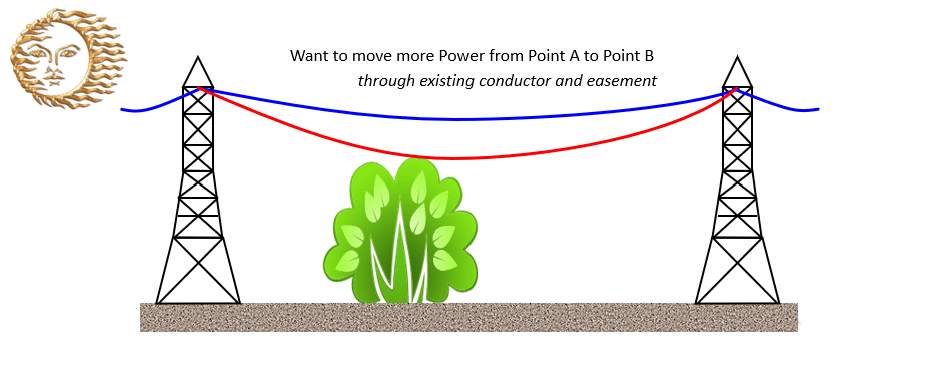

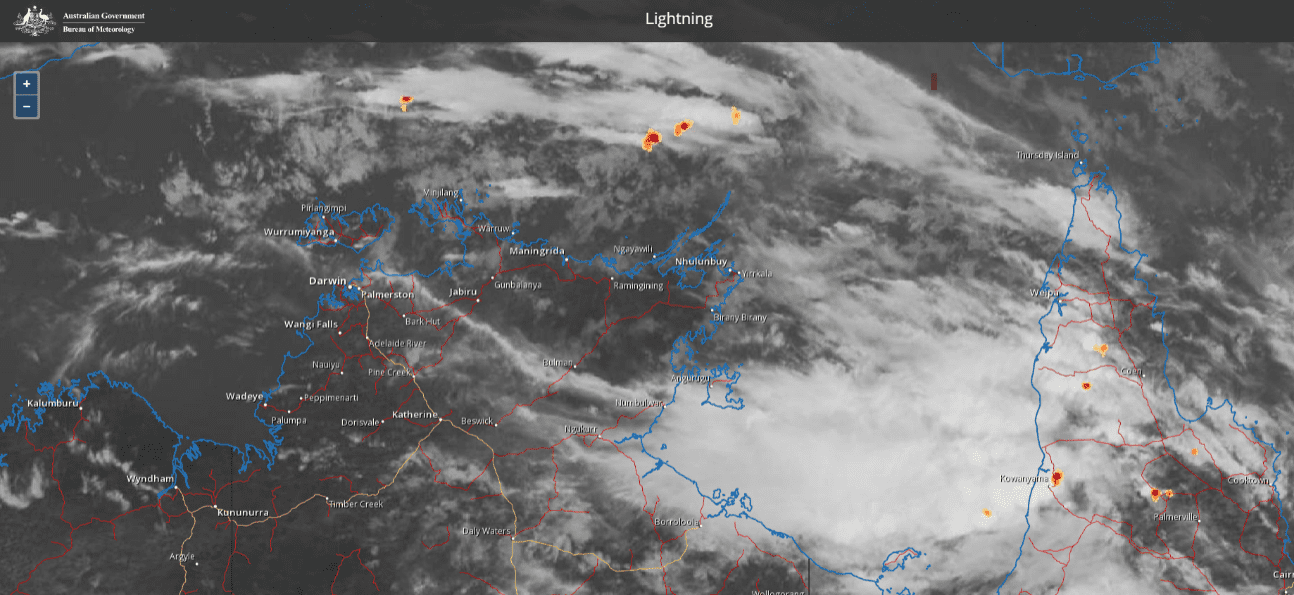

4. Line Rating

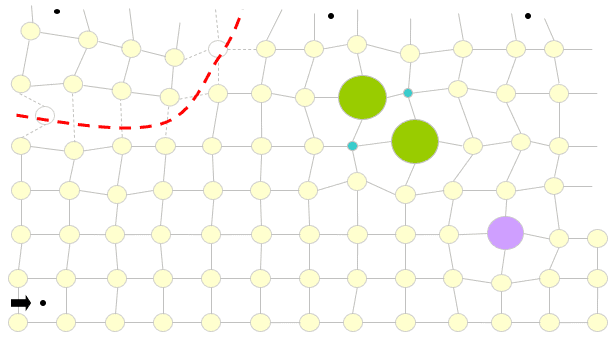

What aspects of a conductor remain constant over time and how is the performance impacted by the things that vary?

Dynamic line rating focuses on the tension of the conductor in the presentation, a combination of monitoring the temperature and tension is ideal.

The variability of wind speed and the importance at low wind speed is highlighted.

The assignment focuses on quality weather data and the observed variability.

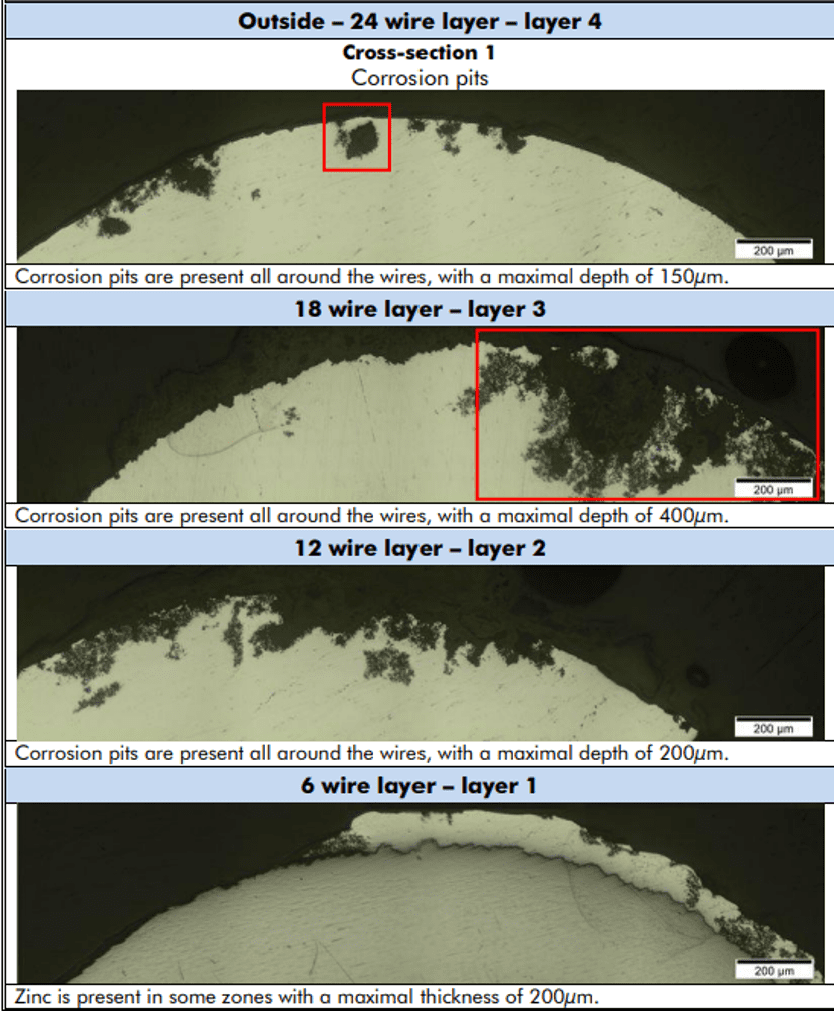

5. Corrosion

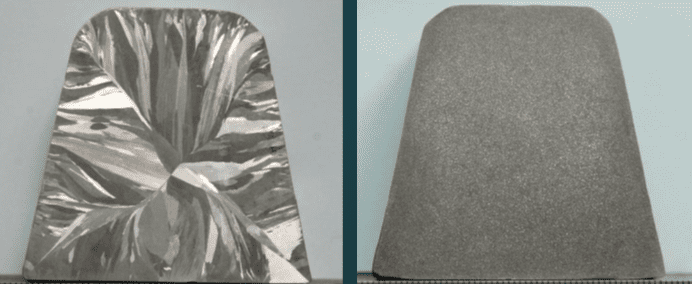

Corrosion concepts covered and examples of samples from the field presented.

The lack of information and examples is lamentable, and participants should be encouraged to make their own observations and dig into their Utilities experience.

The importance of moisture with respect to corrosion cannot be underestimated.

The debate over grease excluding moisture or capturing moisture and dust is to be had.

6. Asset Management

Reflect back on record keeping and how design standards have changed…weather conditions altered, line ratings also.

Focus on data collection and test reports – suppliers, academia, CIGRE and individual Utilities.

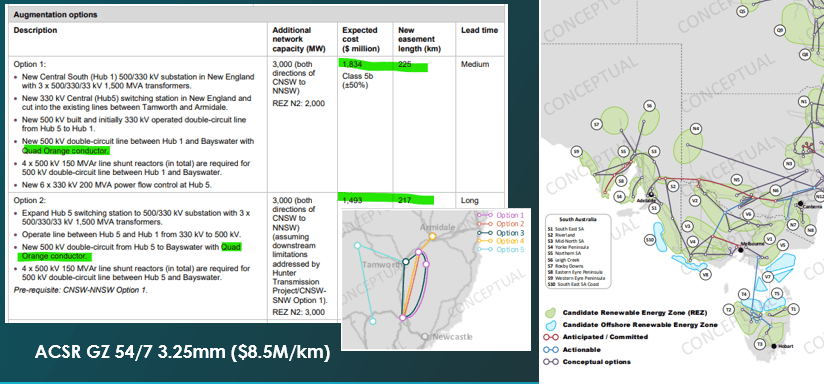

7. Life Cycle Analysis

Carbon footprint of materials and the ongoing line losses impact is examined in detail and different conductors are examined: notably ACSR GZ, AAAC 1120 and HTLS.

Total life cycle cost to be examined for different materials and the implications of using different conductors.

The environmental impacts of bushfires, wildlife and the interaction with overhead conductors is examined.

This module is offered as a standalone session as many non-technical asset managers/ policy bureaucrats and politicians have a required interest in this topic.

8. Bushfires, bats and birds

The role of covered conductors and the different conductor alloys associated are examined.

Different examples from around the world demonstrate the different wildlife interactions and the varying importance of bushfires - electrical assets initiating or being damaged by

9. Vibration

The influence of wind on the performance and life expectancy of overhead conductors is examined.

- Conductor blowout

- Aeolian vibration

- Ice galloping

- Sub conductor oscillation

- Wind motion during installation/ on sheaves

Damper choice is discussed and reference to classic CIGRE techncial collaboration.

Cx values of smooth body/ compact designs are compared to traditiona lround wire constructions and the differences discussed.

10. Bringing it all together

Reflection on weather conditions, corrosion, grease, line losses.

Value chain costs and total cost of ownership considered with some examples

Examples of the design process from mvarious Utilities are presented.

Wind load safety factor and the lack of laboratory data, how should this be included in standards and approved?

Metallurgy of OHL readings

The general readings are highlighted in the Reference Library tab.

CIGRE memebrs are directed to the password protected reading list tab. The large number of CIGRE technical brochures and technical papers are copyright protected and avaialble to memebrs only.

Similarly the AS/NZ Standards are copyright protected - sections are permitted to be discussed and shown foreducational purposes.

Assignments

1. Who is who in the Zoo: review your own network/ Utility; the age of conductors, lien length, types of structures and geography/ vegetation/ climate. Review annual reports from Utilities, AEMO and AER. How does your role fit in?

2. Examine the conductor fleet in detail. Alloy type and voltages.

3. Compare ACSR GZ and AAAC 1120 (same diameter) for sag and span.

4. Examine the solar radiation distributions for Melbourne and Mildura.

5. Corrosion examples from your own network (or consider whether an all aluminium alloy conductor should be greased or not).

6. Estimate the capital cost for 100km of transmission line (raw materials). Or estimate the cost per annum for maintenance inspection for 1000km of HV transmission.

7. Discuss how much time and effort goes into conductor selection for initial carbon footprint and for total cost of ownership.

8. Discuss the extent of your personal technical library. How can we expand/ share...

9. Present a case study from your own network; or compare three conductors for a hypothetical transmission line (ACSR, AAAC and HTLS: round and compact variants)

Connect With Industry Experts

The metallurgy of overhead lines is a multidimensional aspect encompassing material selection, manufacturing processes, and a deep understanding of the metallurgical properties essential for the reliable and efficient functioning of electrical power distribution systems. Get in touch with us to learn more about us.