Addressing the Challenges of Ageing Infrastructure in the Energy Sector

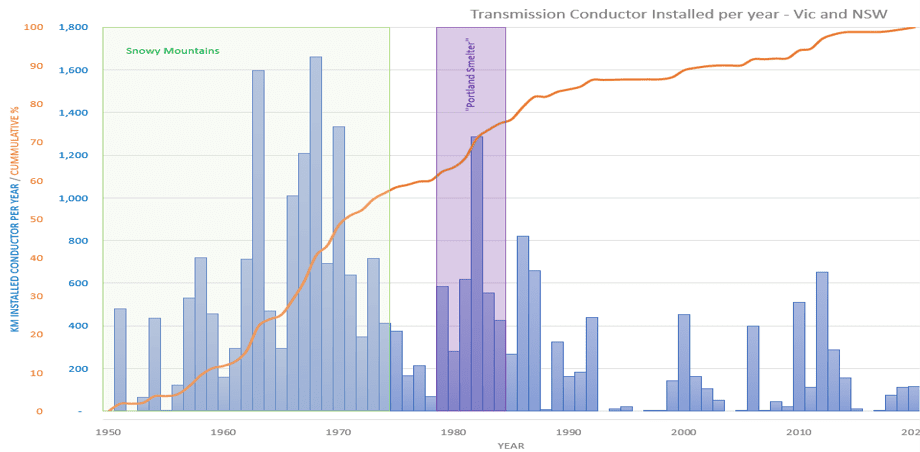

In the states of Victoria and New South Wales, a significant portion—fifty percent—of the transmission network is over 50 years old. This ageing infrastructure presents a pressing concern for the broader energy networks in the coming decade. Compounded by the increasing demands from renewable energy sources, sections of the network originally designed for consumption are now being tasked with generation. This shift places unprecedented strain on the core conductors of the network, demanding exceptional performance to meet evolving energy needs.

While corrosion management remains a feasible approach for ageing infrastructure, conductors possess a finite lifespan and inevitably require replacement. Neglecting this essential maintenance could result in conductor failures, leading to inconvenient outages, disruptions in renewable energy accessibility, and even the potential for devastating bushfires, along with various other social ramifications.

Managing an ageing network demands a comprehensive understanding of overhead line metallurgy. This entails addressing outdated conductor designs, such as galvanized steel wires and hard-drawn aluminium wires, which were prevalent in earlier installations. Moreover, staying abreast of modern materials and designs—such as high-temperature conductors, compact aluminium alloy designs, fully annealed aluminium, and high-performance greases—is essential for effectively maintaining and enhancing the network’s longevity.

To ensure the continued robustness of our energy infrastructure for the next half-century and beyond, it is imperative to invest in ongoing education and development initiatives. By fostering a deep understanding of metallurgical principles and embracing modern advancements, we can fortify our networks to power communities reliably and sustainably into the future.

Mjlee consult offers in depth training of the Metallurgy of Overhead Lines: discover more at www.mjleeconsult.com.au